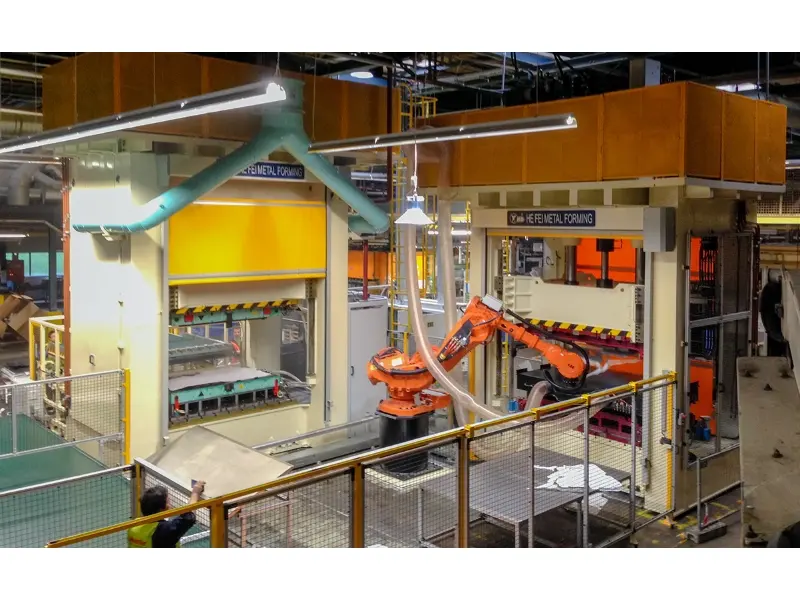

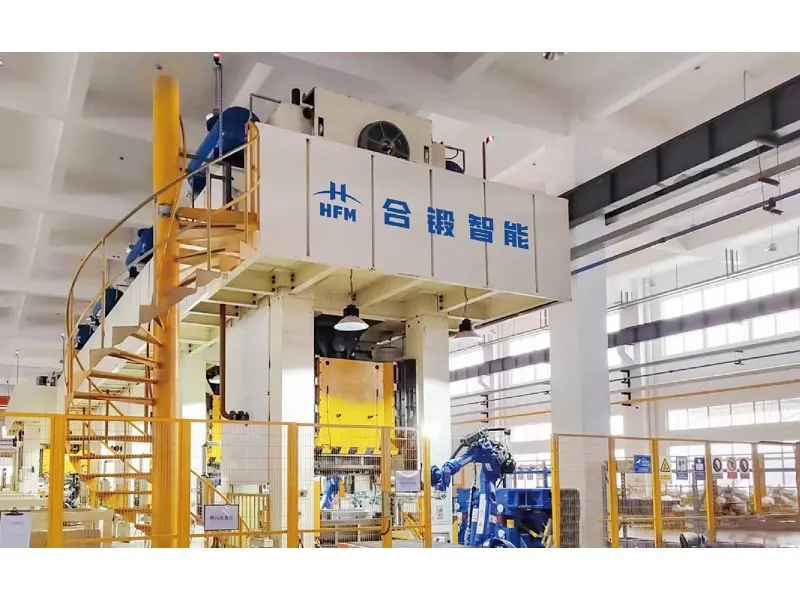

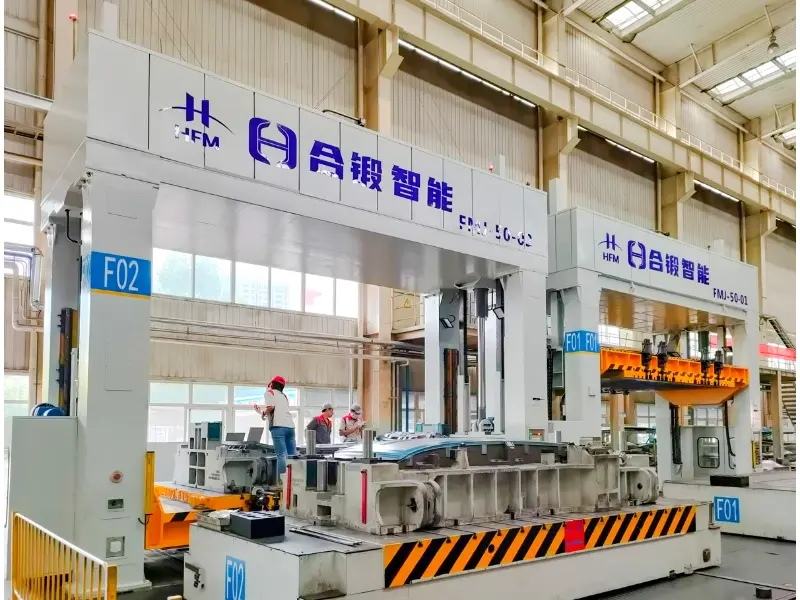

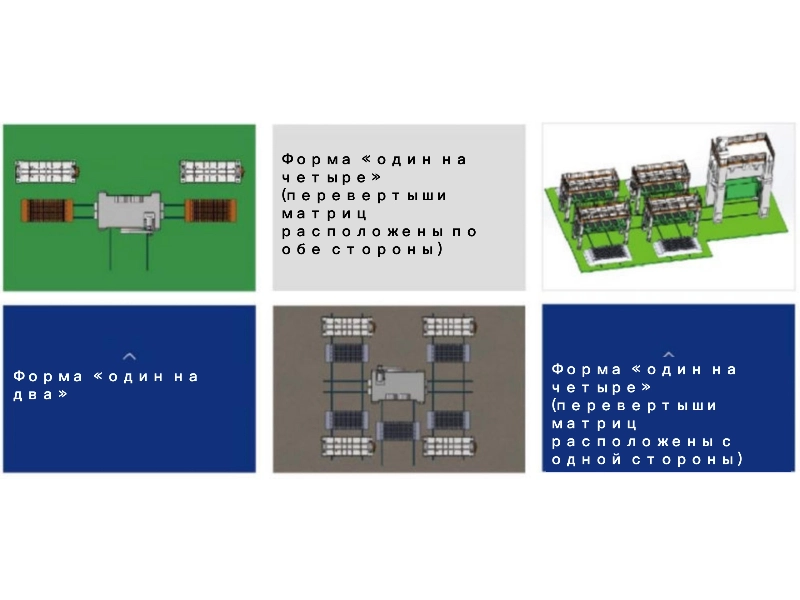

Brief introduction: The first large-scale high-performance flexible one-to-two and one-to-four die testing center in the country can shorten the die adjustment and waiting time in the main press, improving the die adjustment efficiency by 1-3 times. The exchange of dies in different working areas is fully automatic. The clamping of dies is carried out automatically by self-moving or pneumatic lever clamps. The moving platform is equipped with a battery-powered DC drive and high-speed wireless modular communication.

Keywords:large flexible high-performance matrix testing and tuning center

Application areas

Application areas