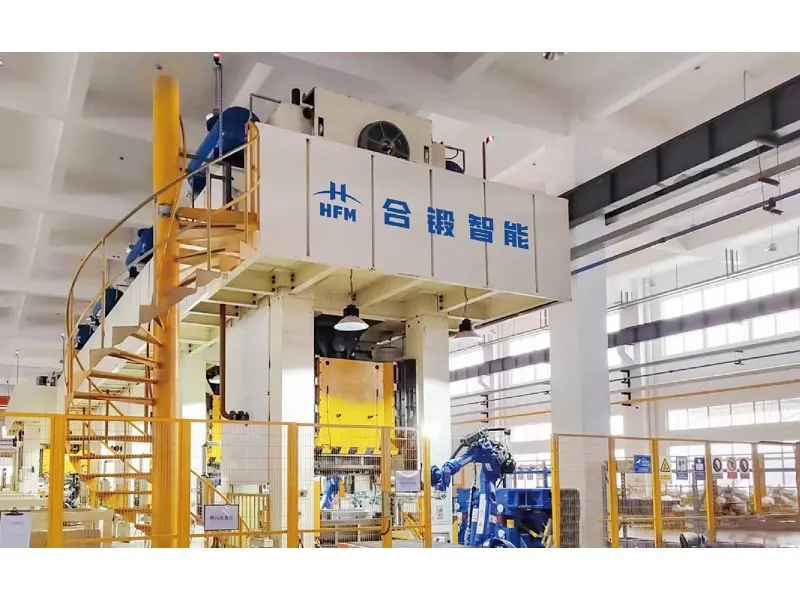

Hydraulic forging press: what is it?

Release time: 2025-10-09

Hydraulic forging presses Hydraulic forging presses are essential equipment used in the metallurgical industry for forming and processing metal components. This article aims to provide a detailed understanding of hydraulic forging presses, their functions, operating principles, applications, and advantages.

Function of hydraulic forging presses

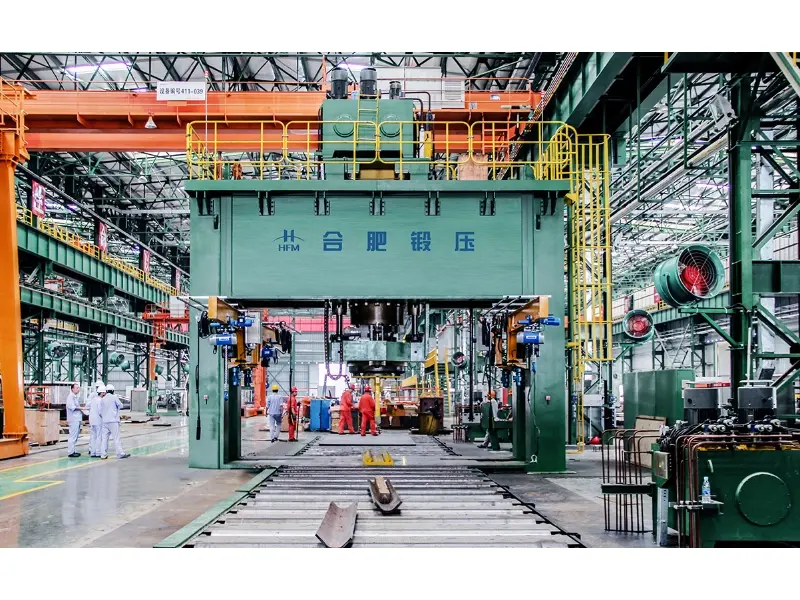

Hydraulic forging presses are designed to apply high pressure to metal workpieces to deform them into the desired shape. They use hydraulic energy to generate the required forging force, which can range from hundreds of tons to several thousand tons depending on the application. The presses are equipped with hydraulic cylinders, pumps, valves, and control systems that regulate and precisely apply the force.

Operating principles

A hydraulic forging press converts hydraulic energy into mechanical force. When hydraulic fluid is pumped into the cylinders, it creates pressure, causing the pistons to move and exert force on the workpiece. The ability to control the press's speed and force makes it suitable for a wide range of forging operations, including hot forging, cold forging, and precision forging.

Types of hydraulic forging presses

There are several types hydraulic forging presses, including unidirectional presses, bidirectional presses, and multi-purpose presses. Unidirectional presses apply force in one direction, while bidirectional presses can apply force in both directions. Multi-purpose presses are equipped with multiple cylinders, allowing for complex forming operations.

Application

Hydraulic forging presses are used in a variety of industries, including automotive, aerospace, energy, and manufacturing. They are used to forge components such as crankshafts, gears, connecting rods, and other critical parts that require high strength and precision. The flexibility and precision provided by hydraulic presses make them suitable for both small-batch and high-volume production.

Advantages of hydraulic forging presses

Using hydraulic forging presses offers several advantages, including the ability to apply high force with precision, uniform forming, reduced material waste, and increased productivity. Furthermore, hydraulic presses can accommodate a variety of tooling configurations and are adaptable to a variety of forging processes.

Conclusion

Hydraulic forging presses Hydraulic forging presses are indispensable tools in the metallurgical industry, enabling the formation and processing of metal blanks with precision and efficiency. Their versatility and ability to perform a wide range of forging operations make them essential for the production of high-quality metal components across a variety of industries. Understanding the functions and applications of hydraulic forging presses is essential for optimizing their use in metallurgical processes.