Study of the hydraulic pressing process

Release date: 2025-11-05

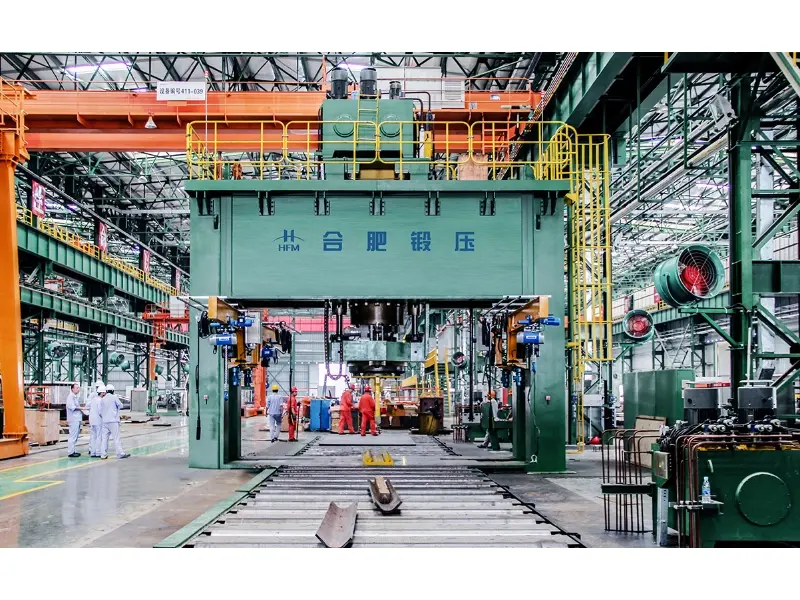

Hydraulic pressing Hydraulic pressing is a widely used manufacturing process that involves shaping and processing metal using a hydraulic press. This technique utilizes the force generated by hydraulic cylinders to apply pressure to the metal, resulting in the desired shape and structure. In this article, we'll take a detailed look at the hydraulic pressing process, its advantages, and applications in various industries.

Hydraulic pressing process:

- Heat: The first step in the hydraulic pressing process is heating the metal to a specific temperature to increase its ductility, which facilitates the forming process. Heating can be accomplished by induction, electrical resistance, or furnace heating, depending on the type of metal being processed.

- Preparing the stamp: A stamp is a specialized tool with a specific shape that is used to shape metal. A stamp is typically made of hardened steel or other durable materials and is designed to meet product requirements.

- Metal placement: Heated metal, called a blank, is placed on the bottom of the die, also called the anvil, of a hydraulic press.

- Applying pressure: A hydraulic press applies significant force to the metal through hydraulic cylinders. The applied pressure causes the metal to deform, forming the shape of the die, resulting in the desired product.

- Cooling and finishing: Once the metal has taken the desired shape, it is removed from the die and allowed to cool. Additional finishing processes, such as machining, grinding, or polishing, may be performed to achieve the desired surface texture and dimensional accuracy.

Advantages of hydraulic pressing:

- High strength and durability: Hydraulic pressing allows the production of components with excellent strength and durability due to the compression and deformation of metal under high pressure.

- Improved grain structure: The pressure applied during hydraulic pressing refines the grain structure of the metal, which contributes to improved mechanical properties and fatigue resistance.

- Complex forms: This pressing method allows for the production of complex shapes that would be difficult to achieve using other manufacturing methods.

- Economy: Hydraulic pressing has economic advantages over alternative methods, especially for mass production.

Application of hydraulic pressing

Hydraulic pressing is used in a variety of industries, including:

- Automotive industry: Components such as crankshafts, connecting rods and gears are often manufactured using hydraulic pressing.

- Aerospace industry: Key aircraft parts such as turbine disks, landing gear components and engine shafts can be produced using this process.

- Oil and gas industry: Valves, flanges and other heavy-duty components used in the oil and gas industry can benefit from the strength and durability achieved through hydraulic pressing.

Conclusion

Hydraulic pressing Hydraulic pressing is a versatile and efficient metalworking process that produces high-quality components with excellent strength and durability. Thanks to its ability to form complex geometries and a wide range of applications in industries such as automotive, aircraft, and oil and gas, hydraulic pressing continues to play a vital role in modern manufacturing.