Mechanical Press vs. Hydraulic Press: Which One is Right for Your Production Needs?

Release time: December 25, 2025

Choosing the right press for your production can significantly impact production efficiency, product quality, and long-term operating costs. In the world of industrial presses, two main options dominate: mechanical presses And hydraulic pressesBoth presses are important for different applications, but how do you choose which one is best for your production process?

Basics: Mechanical Press vs. Hydraulic Press

Mechanical press uses a flywheel and mechanical linkage to generate force, typically through a crank or cam mechanism. This type of press is known for its high operating speed and consistent power throughout each stroke, making it ideal for high-volume stamping and forming applications. On the other hand, hydraulic press Uses hydraulic fluid to generate force that can be adjusted to suit the task at hand. Hydraulic presses are known for their versatility and ability to apply adjustable pressure, making them suitable for operations requiring greater precision and controlled pressure.

The main differences between mechanical and hydraulic presses

1.Speed and efficiency

Mechanical presses are designed for high-speed production. Their robust design allows them to quickly and efficiently perform repetitive tasks, making them particularly useful for industries such as automotive and electronics, where high productivity is critical.

Hydraulic presses, while slower than mechanical presses, offer greater flexibility in pressure adjustment and are ideal for tasks requiring more precise control, such as forming complex shapes or delicate materials.

2.Power control

One of the standout features of hydraulic presses is their ability to adjust force levels in real time. This makes them ideal for working with materials that require varying pressure throughout the process. Mechanical presses, on the other hand, provide a more constant force, which may be more suitable for simple, high-volume applications where varying pressure is not required.

3. Durability and maintenance

Mechanical presses They are generally known for their durability and low maintenance costs. They have fewer moving parts and wear out more slowly over time, making them a more economical option for long-term use.

In contrast, hydraulic presses may require more frequent maintenance due to the complexity of their hydraulic systems. However, their versatility and ability to handle a variety of materials and shapes justify the higher maintenance costs.

4. Flexibility for working with materials

Hydraulic presses They excel at handling materials that require slow and controlled application of force, such as rubber or some composites. This makes them ideal for industries such as aerospace or shipbuilding, where material integrity is critical. Mechanical presses, while effective for quickly completing high-volume tasks, may not be as versatile when it comes to handling a wide range of materials.

How to choose the right press for your production

Choosing between a mechanical or hydraulic press depends largely on your specific needs. Consider the following factors:

Production volume: If you need high speed production with consistent results, mechanical press — the best choice.

Material type: For working with delicate or difficult materials that require precise force control, it is better to choose hydraulic press.

Speed vs. flexibilityIf speed and efficiency are your primary goals, mechanical presses will meet your requirements. If flexibility and adjustable force are your primary goals, hydraulic presses are a better choice.

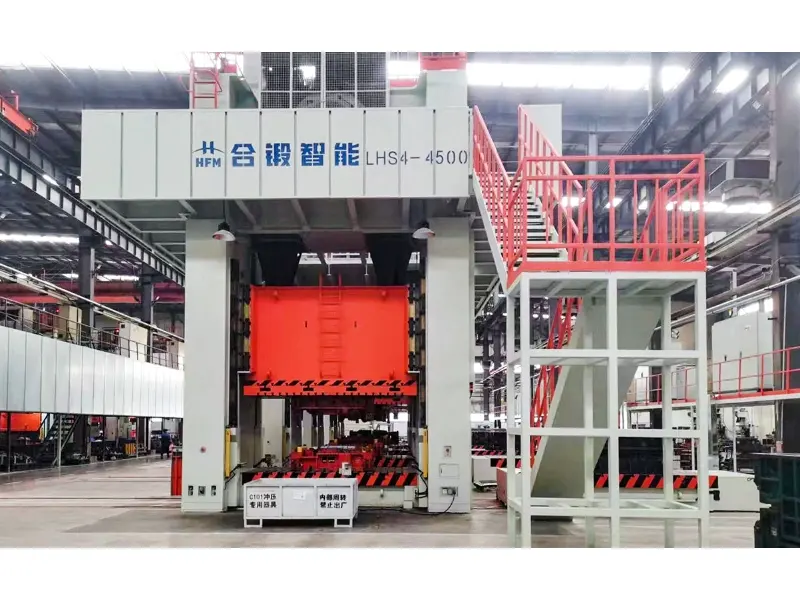

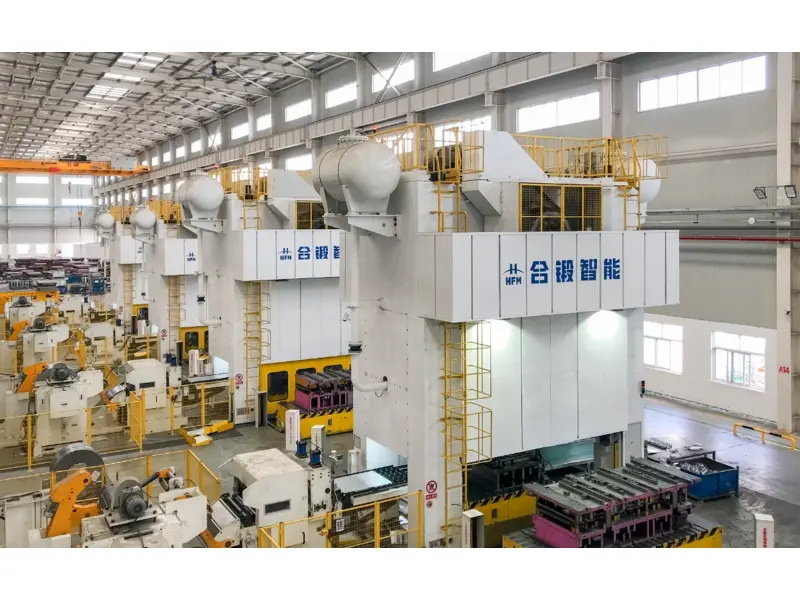

Hefei Metalforming: Expert in mechanical and hydraulic presses

Company Hefei Metalforming Intelligent Manufacturing Co., Ltd. (HFM) has over 70 years of experience in the field of press equipment manufacturing. Since its founding in 1951, HFM has held a leading position in the production mechanical And hydraulic presses, as well as automated and complex production lines. Our products, which range in capacity from 800 kN to 200,000 kN, are used in industries such as automotive, aerospace, light industry, and consumer electronics.

Whether you need it or not mechanical press for high speed production or hydraulic press For precision operations, we have the necessary experience to provide optimal solutions. Our wide range of products, including automated lines and complete production lines, ensures we meet the needs of all customers, from small to large businesses.