Commonly used types of metal presses

Release time: 2025-09-27

Metal presses, also known as pressing machines or stamping presses, are widely used in manufacturing processes such as cutting, bending, punching, and forming metal materials. There are several types of metal presses, each designed for specific tasks. The most common types are listed below:

Mechanical press

Operating principle: Mechanical presses They use a flywheel to store energy, which is then transferred to the piston (the moving part of the press) to perform the metalworking operation.

Main use: These presses are often used for high speed operations such as stamping, punching and blanking.

Hydraulic press

Operating principleHydraulic presses use pressurized hydraulic fluid to drive a piston, which moves the press ram. Pressure is generated by a pump, which forces fluid into a cylinder, which then applies force to the material.

Main useHydraulic presses are versatile and used for deep drawing, forming, and metalworking. They are also frequently used in industries such as automotive and aerospace.

Pneumatic press

Operating principlePneumatic presses use compressed air to drive a piston, which moves the press piston. Air pressure is regulated by valves, allowing for precise control of the applied force.

Main use: Used for lighter applications such as assembly, forming or light punching.

Energy press

Operating principleThis is a broad category that includes both mechanical and hydraulic presses used in industry to apply force to metalworking. Power presses can be used for stamping, punching, cutting, and bending.

Main useEnergy presses are used in industries such as automotive, electrical components and consumer goods manufacturing.

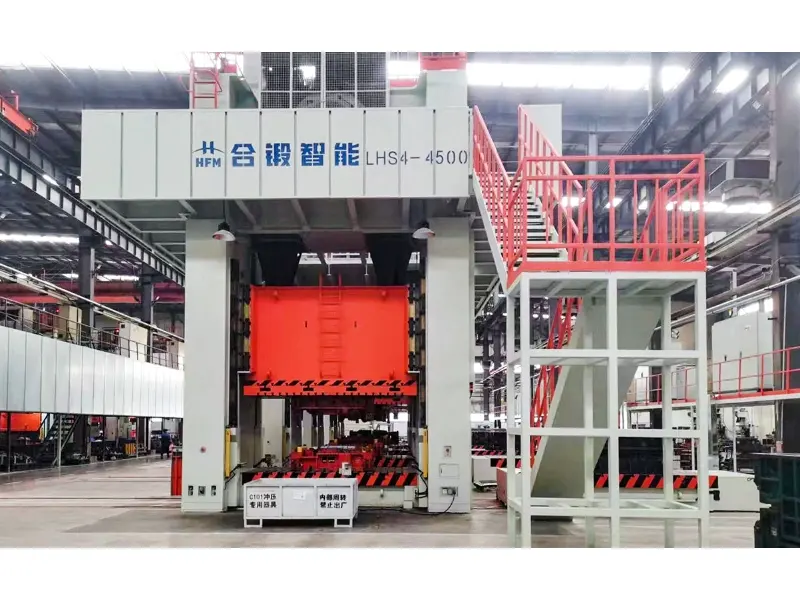

Straight-sided press

Operating principleStraight-sided presses have a straight, rigid frame and are typically used for high-precision, heavy-duty operations. The frame ensures better force distribution across the material being processed.

Main use: Ideal for die cutting, stamping and other processes requiring high force or precision.

Flywheel press

Operating principleFlywheel presses store energy in a flywheel and release it to operate a piston. The flywheel maintains inertia, keeping the piston moving at a constant speed.

Main use: Used for medium and high speed operations such as punching, cutting and shearing.

Double knee press

Operating principle: Double-knee presses have two knees to create more complex piston movements, making them suitable for complex or high-precision operations.

Main use: Used in stamping and metal processing requiring higher precision.

Impact Press

Operating principle: Impact press equipment applies a sharp, high force impact to the workpiece, making it ideal for forging, stamping and other high force operations.

Main use: Used in processes such as forging, metal forming and high energy stamping.

Cold forging press

Operating principleCold forging presses are specially designed to form metal at room temperature by applying high force to compress and shape the material.

Main use: Widely used in industries where small, high-precision parts are required, such as automotive, aerospace and electronics.

Every type of pressing machine Metal pressing machines are designed to perform specific tasks, from high-speed stamping to high-energy forming and deep drawing. When selecting a pressing machine, it's important to consider the force, speed, and complexity requirements of the operations being performed.