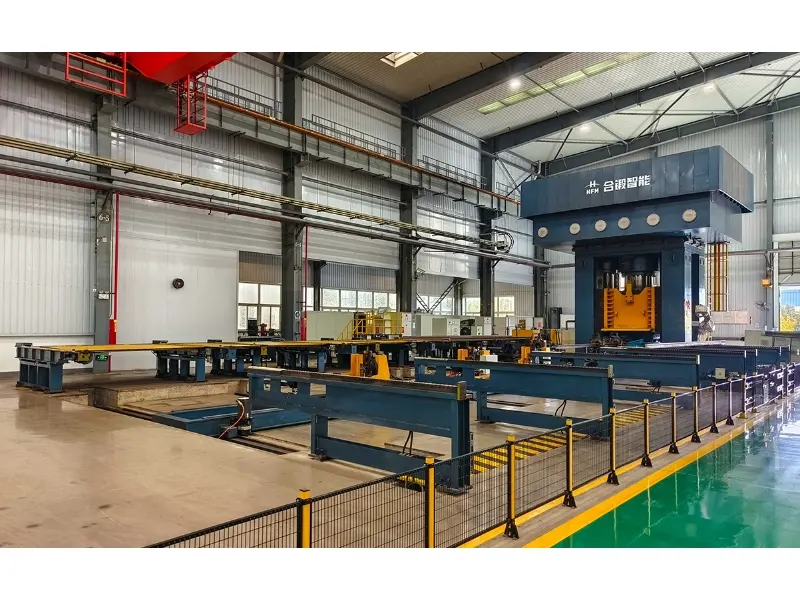

Brief introduction:The fully automatic railway switch forging production line adopts pre-stressed frame structure, fully automatic line loading and unloading system, pre-heating and post-heat treatment system, multi-station section forging, die temperature control system and fully automatic irrigation system and other new technologies. It is the most functional and technologically advanced fully automatic railway switch forging production line in the country.

Key words:fully automated production line for forging railway switches

Application areas

Application areas