Why Closed-loop Four-Point Mechanical Presses Are Becoming a Smart Choice for Modern Metal Forming

Release date: 2026-01-06

If you've been working in metal forming for a while, you've probably noticed a trend: parts are getting larger, thinner, and more complex, and traditional presses are starting to fail. Problems with molding uniformity, consistent quality, and increased defects are emerging. That's why more and more manufacturers are choosing Closed four-point mechanical presses.

In the company Metalforming We communicate daily with clients who are looking for more stable solutions, predictable results, and fewer problems on the shop floor. And in many cases, the closed-loop four-point press proves to be the solution that truly makes a difference.

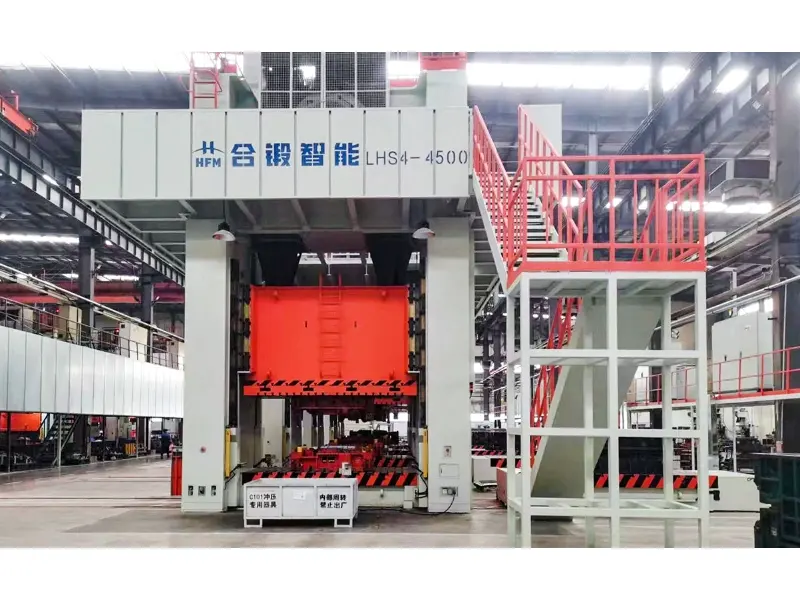

What is a closed four-point mechanical press?

Let us explain without unnecessary complications.

Four-point design means that the slider is supported and loaded evenly at four points, rather than at one or two.

Closed frame - is a completely closed, box-shaped structure, which is significantly more rigid than an open C-shaped one.

The result is a press that exerts pressure evenly and stably, with virtually no body deformation. This is especially important when working with large workpieces, deep drawings, and parts where appearance and precision are critical.

Why are the four-point and closed-loop design so important?

In practice, uneven force is one of the main causes of quality problems. It can lead to warping, uneven thickness, and accelerated die wear.

The closed-loop four-point mechanical press helps avoid these problems by:

- uniform distribution of force over the entire surface of the slider

- minimal deformation of the frame during operation

- more even and stable parts

- reducing the load on the tooling

This design is especially in demand in the production of automotive components, household appliances, metal housings and panels.

Where are such presses most often used?

In our experience, closed-loop four-point mechanical presses are excellent for:

- large-sized sheet metal parts

- progressive and transfer stamps

- automobile body and power elements

- housings and panels of household appliances

- serial and mass production

If you work with wide dies, long production cycles and high quality requirements, such a press can significantly simplify the process.

Practical benefits in daily work

For operators and production managers, it's not theory that matters most, but actual results. This is where closed-loop four-point presses excel:

Stable quality of parts

Each press stroke produces a predictable result.

Extended service life of stamps

Uniform loading reduces the risk of injury.

Quiet and reliable operation

The closed frame reduces vibration and unwanted movement.

Convenience for automation

These presses can be easily integrated with feeding systems, transfers and robots.

The result is less downtime, fewer adjustments, and more confidence in the production process.

What to look for when choosing a press?

Not all closed-loop four-point mechanical presses are created equal. When choosing equipment, consider:

- matching the effort to real production tasks

- accuracy and repeatability of the slider movement

- ease of management and maintenance

- manufacturer's experience and quality of service support

A press is an investment that will last for years, so a reliable partner is just as important as the machine itself.

How Metalforming Helps Achieve Your Manufacturing Goals

IN Metalforming We design and manufacture closed-loop four-point mechanical presses tailored to real-world operating conditions. We value not only paper specifications but also the equipment's reliable operation over many years.

We offer:

- a wide range of efforts for different tasks

- strong and rigid frame designs

- flexible configurations for automated lines

- reliable technical support from an experienced team

Whether you're upgrading an existing facility or launching a new project, we can help you find the perfect solution for your process.

Conclusion

Closed four-point mechanical press - it's not about complexity, but about stability, predictability and efficiencyFor many businesses, it is becoming a key element that improves product quality and reduces long-term costs.

If you are considering new press equipment solutions or want to learn how a closed four-point design can benefit your specific production, Metalforming is always ready for dialogueExplore our solutions on our website or contact our team—we'll be happy to help you find the best option for your needs.