Application of large mechanical punching presses in the automotive industry

Release time: 2025-09-13

Large mechanical punching presses — are industrial devices with powerful pressing ability, which play a vital role in the automobile industry. Using enormous pressure, these presses can accurately cut out various complex parts from metal sheets. They are widely used in the production process of automobile bodies, chassis and other key components, being the "production engine" of modern automobile manufacturing.

Operating principle

A large mechanical punching press consists of three main parts:

- Frame: This is the frame of the press that supports all its components and ensures the stability of the device when exposed to enormous pressure.

- Plunger: This is the part of the press that can move up and down. The plunger is where the upper part of the mold is installed.

- Drive system: Provides movement of the plunger. When the plunger moves down, it compresses the mold and a lot of pressure is applied to the metal, which allows the part to be formed.

During operation, a metal sheet is placed on the bottom of the mold. The drive system then moves the plunger, which moves downwards, squeezing the upper and lower molds. Due to the enormous pressure, the metal undergoes plastic deformation and takes the shape of the mold.

Main characteristics

- Enormous pressure: A large mechanical press can create pressure of several hundred or even thousands of tons, which allows working with thick and high-strength metal.

- High precision: Despite its enormous power, the press maintains high precision, ensuring ideal dimensions and shapes of cut parts.

- High performance: The press is capable of operating quickly and continuously, making it ideal for large-scale production with automation.

- Multifunctionality: In addition to blanking, the press can also perform various operations such as deep drawing, bending, forming and punching.

Application in the automotive industry

1. Car body parts

In car manufacturing, the body is one of the most complex and precise parts. The body can be divided into external and internal elements, and punch press widely used in both cases:

- External elements: Such as door panels, hood, roof, fenders and trunk lid. These parts require high precision of surface and curvature. Large press allows to achieve smooth and flawless surface, which is important for subsequent painting.

- Internal elements: These parts make up the body frame and play a vital role in the safety of the vehicle. They include components such as door interior panels, pillars, cross members and beams. They are made using stronger, thicker metal and a large press with powerful pressure allows these parts to be accurately cut, formed and punched, ensuring the rigidity and safety of the body.

2. Car chassis parts

The chassis of a car is the foundation on which the body and engine are mounted. The requirements for strength and rigidity are extremely high for chassis parts. The mechanical punching press plays a key role in the production of chassis components such as the suspension and frame:

- Suspension parts: For example, suspension arms and control arms, which require high strength and durability. The large press can accurately perform deep drawing and forming of thick metal, meeting strict mechanical requirements.

- Frame and beams: In monocoque vehicles, the frame is the main structural element. The large press can accurately cut and shape thick frame parts, ensuring the strength and stability of the entire vehicle.

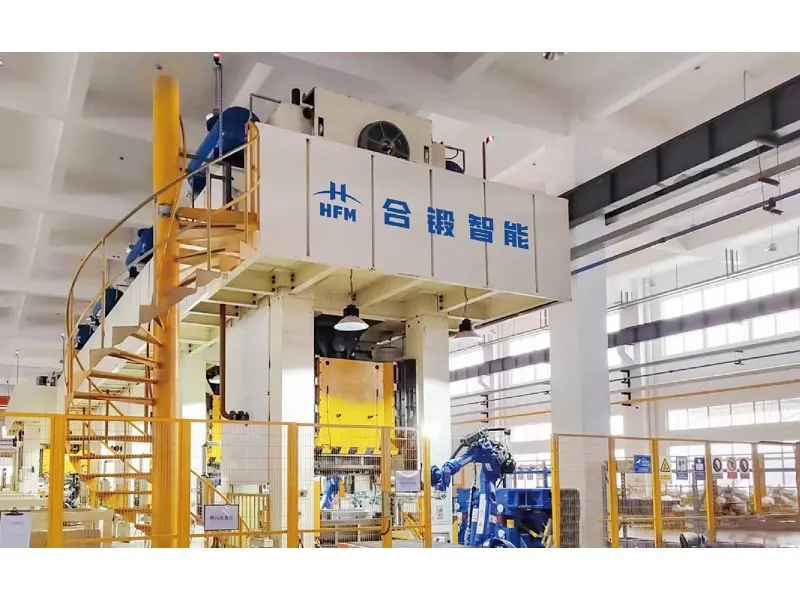

3. Role in automated production lines

In modern automobile factories, large punching presses do not operate alone, but are closely integrated with automated equipment to form highly efficient production lines. These automated lines significantly increase productivity and part consistency:

- Automation: Robotic loaders remove metal sheets from stacks and place them precisely in the mold. Once the pressing is complete, another robot picks up the part and passes it on to the next steps, such as cutting, punching or welding.

- High performance: Automated lines allow several operations to be performed per minute, which significantly reduces production time and increases efficiency.

- Stability and consistency: Automation ensures precise dimensions and high quality of each part, minimizing human errors and the number of defects.

Conclusion

Large mechanical punching presses play an indispensable role in the automobile industry. Not only do they enable efficient and accurate production of body, interior and chassis parts, but they also enable mass, high-quality and automated production through integration with automated systems. With the development of the automobile industry, the technology and application of the punch press will continue to promote progress, improving production processes and part quality.