Product details

He Duan Intelligent Systems has developed equipment packages that meet various composite molding technologies, from the common commercial technologies to the advanced mass molding technologies. Automated mass production technologies meet the productivity requirements. Integrated creativity of complex devices and continuous production technologies reduce costs. At present, we have successfully transferred dozens of hydraulic presses of production lines adapted to RTM molding technologies, ensuring mass production of parts. The quality of creativity exceeds the expected results.

Purpose:

- Preforming of composite materials.

Composition of the production line:

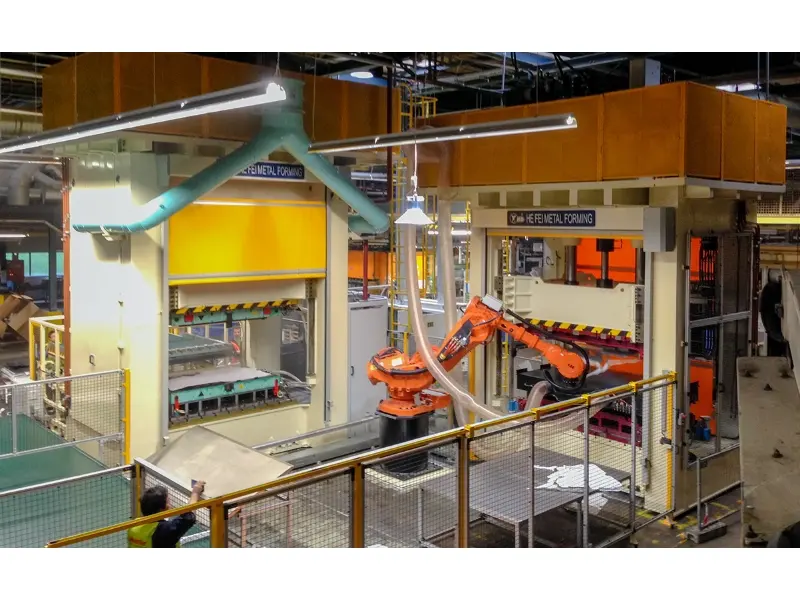

The production line consists of: a stack loading tube (containing a pallet, a guide rod), a module 2D code scanning system, R1/R2 robotic arms, equipped with top loading equipment, equipped with bottom unloading equipment, an electric heating system, an unloading platform, a pre-press hydraulic press, electric controls, safety guard fences, etc., which ensures full automation of production, and also applies marking and scanning of each job, providing data tracking, which is tightly integrated with the development of modern industry.

Technical elements of implementation:

- The automated production line for preforming composite materials consists of loading components, an external loading platform, an internal loading platform and an automatic rotation device. The external loading platform, the internal loading platform are connected to the driver of the automatic rotation electric motor;

- The heating platform is located below the loading component. This heating platform controls the temperature by PID proportional adjustment. The total temperature difference on the heating platform is less than 6 ° C. The lower platform and several rows of steel wire on this lower platform can lift the material after heating the woven composite for easy gripping;

- The next step after the heating platform is the preforming press, which converts the 2D laminated element into a 3D preform using a preform die. After pressing, the part is picked up by an unloading manipulator and placed on a conveyor belt for unloading.

Application areas

Application areas