Different types of presses used in forging

Release time: 2025-10-17

Introduction

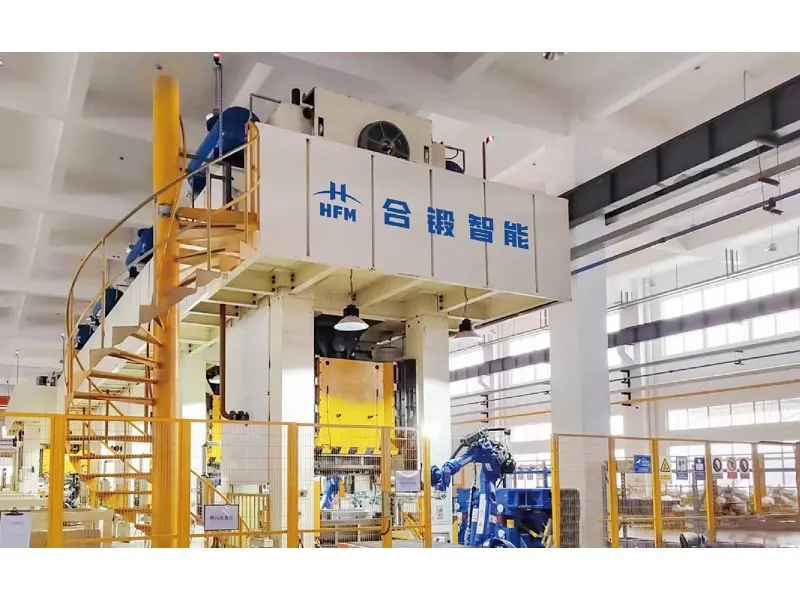

Forging is a metalworking process using compressive forces. One of the key components in the forging process is the press, which applies the necessary force to deform the metal workpiece. Several types of presses are used in forging, each with its own unique capabilities and applications.

Hydraulic press

Hydraulic presses A hydraulic press is one of the most common types of presses used in forging. They use hydraulic cylinders to generate the necessary force to shape a metal workpiece. Hydraulic presses are known for their high strength and versatility, making them suitable for a wide range of forging operations.

Mechanical press

Mechanical presses — Another type of press often used in forging. These presses use mechanical mechanisms, such as flywheels and cranks, to supply the necessary force for forging operations. Mechanical presses are known for their high speed and are often used for mass production.

Screw press

Screw presses These presses utilize a screw mechanism to generate the necessary force for forging. These presses are known for their precise control of the forming process, making them suitable for producing complex and detailed parts. Screw presses are often used in the aerospace and automotive industries.

Hydraulic open die press

Hydraulic open die presses Specially designed for open-die forging, where the metal workpiece is not confined within the mold, these presses offer flexibility in processing large and asymmetrical workpieces, making them ideal for producing components such as shafts, rods, and rings.

Mechanical press for closed dies

Closed die mechanical presses Closed-die forging presses are used for closed-die forging, where the workpiece is enclosed in a mold to form it into the desired shape. These presses are known for their high precision and repeatability, making them suitable for producing complex and high-precision components.

Conclusion

The selection of a forging press depends on the specific requirements of the forging process, including the type of workpiece, the desired shape, and the production volume. Each press type has its own advantages and limitations, and understanding the characteristics of each is essential for achieving efficient and high-quality forging. Careful selection of the appropriate press allows manufacturers to optimize their forging processes and produce high-quality forged components for a variety of industries.