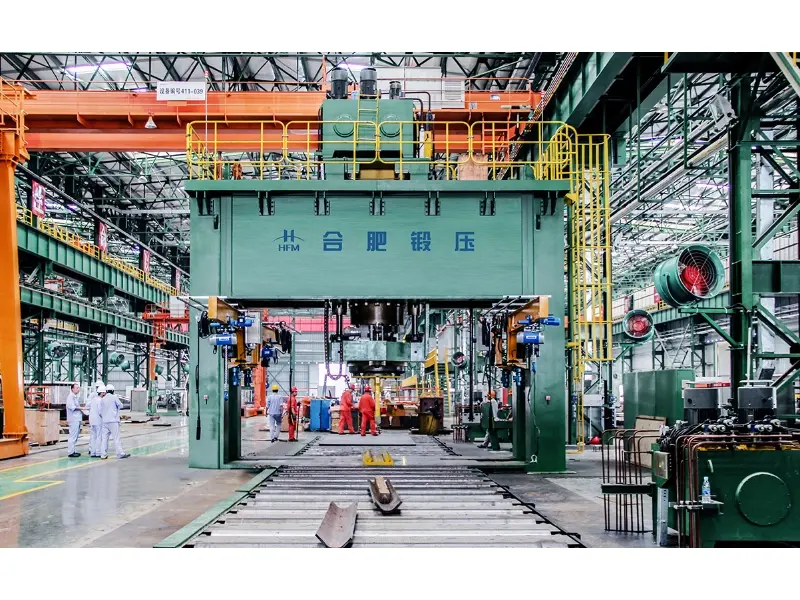

Brief Description: This series of products have high working speed and are equipped with automatic irrigation and lubrication systems for dies. The hydraulic system uses electro-hydraulic proportional servo system, ensuring high pressure and positioning accuracy, which can meet the hydraulic press requirements for various technological processes. The parts made by the matrix forging method can be produced with little or no shearing. This ensures high productivity in the manufacture of products and low costs, so this method is increasingly used in mechanical engineering. The main applications are automobile manufacturing, construction machinery, shipbuilding, standard parts processing and other industries.

Key words: hydraulic press for metal extrusion/thermal material forging

Application areas

Application areas