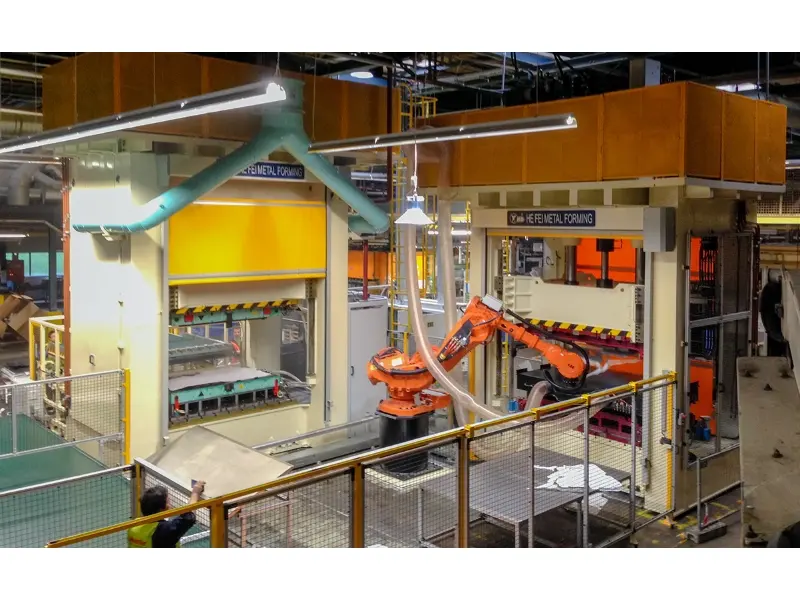

Brief Description: This series of products adopts a frame structure with pre-tensioning rods and a split block. The hydraulic column has guides on eight surfaces at four corners, ensuring high resistance to offset load. With the exclusive delta control technology for mold debugging, high positioning accuracy and speed of the hydraulic column are ensured, which guarantees the durability of the equipment accuracy and rigidity. The hydraulic presses of this series are equipped with a device for turning the upper mold by 180 degrees, which facilitates its debugging. This hydraulic press can be additionally ordered with a drive on a servo motor and a pump, which can reduce energy consumption by more than 80% and reduce the noise level by 10-30 decibels.

Keywords:

Hydraulic press with servo amplifier for debugging and testing of molds

Hydraulic press with servo amplifier for debugging and testing of molds

Application areas

Application areas