Product Center

Product Center

-

Product Details The multilayer press is the key equipment for the final molding of copper-plated printed circuit boards. This automatic production line is a 24-layer double multilayer press automatic production line. It realizes the domestic production of advanced multilayer press for the first time, filling the gap in the technology of vacuum multilayer press in the country, breaking the dependence on imported […]

-

Product Details This hydraulic press is equipped with automatic material loading device, automatic material unloading device, automatic die heating device, die vacuum device and system, automatic powder leveling device, automatic cartridge clamping device, lower pneumatic die rod changing device, die heating and die rod changing device. Functionally complete, […]

-

Product Details He Duan Intelligent Systems has developed complete equipment packages that meet various composite molding technologies, from the common commercial technologies to the advanced mass molding technologies. Automated mass production technologies meet productivity requirements. Integrated creativity of complex devices and continuous production technologies reduce costs. At present, we have successfully transferred dozens of hydraulic presses of production lines adapted to RTM molding technologies, achieving mass production of parts. The quality of creativity exceeds the expected results. Purpose: Composition of the production line: The production line consists of: a stack loading tube (containing a pallet, a guide rod), a module two-dimensional code scanning system, R1/R2 robotic arms, equipped with top loading equipment, equipped with bottom unloading equipment, an electric heating system, an unloading platform, a pre-press hydraulic press, electric controls, and safety fences, etc., which ensures full automation of production, and also applies marking and scanning of each job, ensuring data tracking, which is closely integrated with the development of modern industry. Technical elements of implementation:

Hydraulic Press

-

The automatic cutting press machine production line consists of mechanical cutting press machine, automatic material feeding system and automatic stacking system. It is used to cut thick sheets for automobile chassis parts, interior panels, exterior panels, etc. The production rhythm can reach 20-60 strokes per minute. Specifications: Technical Parameters: Name Unit JH36C-400 JH36C-500 […]

-

Step die press machine is suitable for mass production of small parts by drawing method, has the technical characteristics of high efficiency, technology maturity and reliability. Step die production line is composed of mechanical step die press machine and automatic material feeding system, the production rhythm can reach 15-60 strokes per minute. Technical Parameters: Technical Parameters: Name Unit […]

-

Technical Specifications: Technical Parameters: Name Unit JH31-400 JH31-500 JH31-630 JH31-800 JH31-1000 JH31-1250 JH31-1600 JH31-2000 Nominal Force Kilonewton (kN) 4,000 5,000 6.3 8.0 10,000 12,500 16,000 20,000 Stroke at Nominal Force Millimeter (mm) 13 13 13 13 13 13 13 13 Piston Stroke Length Knocks/minute (spm) 300 400 400 500 500 500 500 500 Frequency […]

Mechanical Press

-

Product Details The multilayer press is the key equipment for the final molding of copper-plated printed circuit boards. This automatic production line is a 24-layer double multilayer press automatic production line. It realizes the domestic production of advanced multilayer press for the first time, filling the gap in the technology of vacuum multilayer press in the country, breaking the dependence on imported […]

-

Product Details This hydraulic press is equipped with automatic material loading device, automatic material unloading device, automatic die heating device, die vacuum device and system, automatic powder leveling device, automatic cartridge clamping device, lower pneumatic die rod changing device, die heating and die rod changing device. Functionally complete, […]

-

Product Details He Duan Intelligent Systems has developed complete equipment packages that meet various composite molding technologies, from the common commercial technologies to the advanced mass molding technologies. Automated mass production technologies meet productivity requirements. Integrated creativity of complex devices and continuous production technologies reduce costs. At present, we have successfully transferred dozens of hydraulic presses of production lines adapted to RTM molding technologies, achieving mass production of parts. The quality of creativity exceeds the expected results. Purpose: Composition of the production line: The production line consists of: a stack loading tube (containing a pallet, a guide rod), a module two-dimensional code scanning system, R1/R2 robotic arms, equipped with top loading equipment, equipped with bottom unloading equipment, an electric heating system, an unloading platform, a pre-press hydraulic press, electric controls, and safety fences, etc., which ensures full automation of production, and also applies marking and scanning of each job, ensuring data tracking, which is closely integrated with the development of modern industry. Technical elements of implementation:

Hydraulic presses and press accessories

- Hydraulic Press

- Mechanical Press

- Hydraulic presses and press accessories

Application areas

Application areas

Many types of high-tech equipment developed by Heduan have been successfully used in Shenzhou aircraft, spacecraft,

Tiangong missiles, nuclear power, ships and high-speed railway, occupying a leading market share.

-

composite materials

Heduan Intelligent is a company dedicated to the research, development, production and service of molding equipment in the field of ...

Find out more -

household appliances

Heduan Intelligent is a company dedicated to the research, development, production and service of molding equipment in the field of ...

Find out more -

Rail transit

Heduan Intelligent is a company dedicated to the research, development, production and service of molding equipment in the field of ...

Find out more -

ship

Heduan Intelligent is a company dedicated to the research, development, production and service of molding equipment in the field of ...

Find out more -

Other areas, welcome to learn more

See more

o Metalforming

o Metalforming

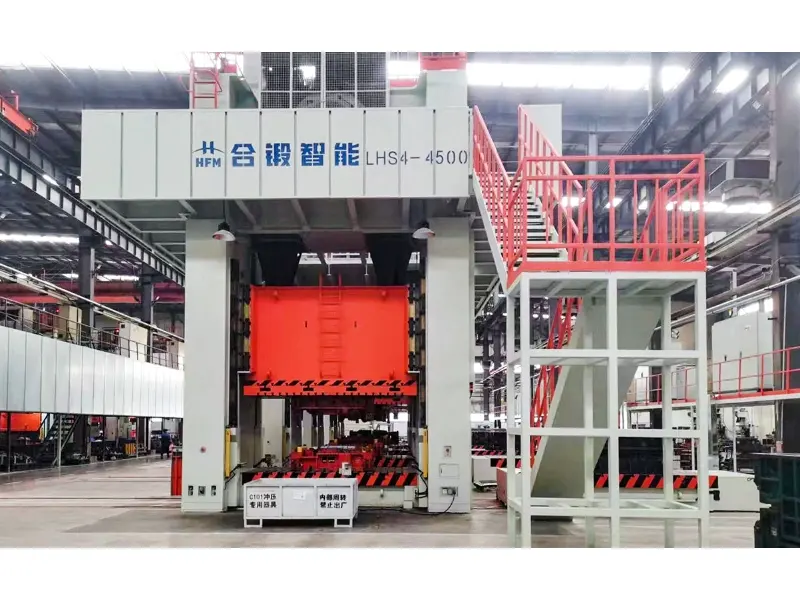

Hefei Metalforming Intelligent Manufacturing Co.,ltd was founded in 1951, abbreviated as HFM, after more than 70 years of accumulated experience, invention and development, HFM has become the leader of China's hydraulic press industry. We have a large-scale equipment manufacturing enterprise integrating the R&D, production, sales and service of hydraulic presses, mechanical presses, laminating presses, automation lines and complete production lines etc. The capacity ranges from 800kN to 200000kN. The products are widely used in such fields as automobile and auto parts manufacturing, metal-plastic, shipbuilding, aerospace, light industry and household electrical appliances, non-metallic material forming

-

.png)

1951

installed in

-

.png)

330,000㎡

Covered area

-

.png)

2014

Listed

-

.png)

1000+

annual productivity

Please leave us a message.

Our engineer will contact you as soon as possible.

Why choose us

Why choose us

Heduan Intelligent is a leading enterprise in the domestic high-quality complete equipment manufacturing industry for molding machines, a national comprehensive technology base for large-scale forging equipment automation and equipment industrialization, and a unit of the vice chairman of the National Strategic Alliance for Innovation in CNC Molding and Stamping Equipment Technology.

-

Rich experience

Talent team and reserve. There are 133 technical personnel, including 56 senior technical personnel. In addition, through the cooperation of universities and industry, such as the Chinese Academy of Sciences, we have more than 200 patents, including 52 invention patents.

.webp)

-

.webp)

Advanced technologies

HFM uses advanced technology from Germany and has great scientific achievements. All these technologies and scientific research achievements reduce the cost of practical production, solve and improve the production technology.

-

production capacity

HFM has strong production capabilities, advanced production equipment and advanced detection means.

.webp)

Product Center

Product Center

-

2026-01-19

2026-01-19Mechanical Press: A Complete Guide to Its Functionality and Applications

Find out more -

2026-01-06

2026-01-06Why Closed-loop Four-Point Mechanical Presses Are Becoming a Smart Choice for Modern Metal Forming

Find out more -

2025-12-25

2025-12-25Mechanical Press vs. Hydraulic Press: Which One is Right for Your Production Needs?

Find out more