Brief introduction:This hydraulic press adopts the technologies of servo proportional hydraulic control, low speed anti-rolling system, electro-hydraulic automatic protection against offset loads, four-angle alignment software, low-speed dynamic step control, multi-channel parametric control and monitoring and other proprietary patent technologies. It is also equipped with various fault diagnosis functions, curve and data generation and display systems, and online monitoring systems for hydraulic oil contamination. This hydraulic press features high control accuracy at ultra-low speed.

Keywords:

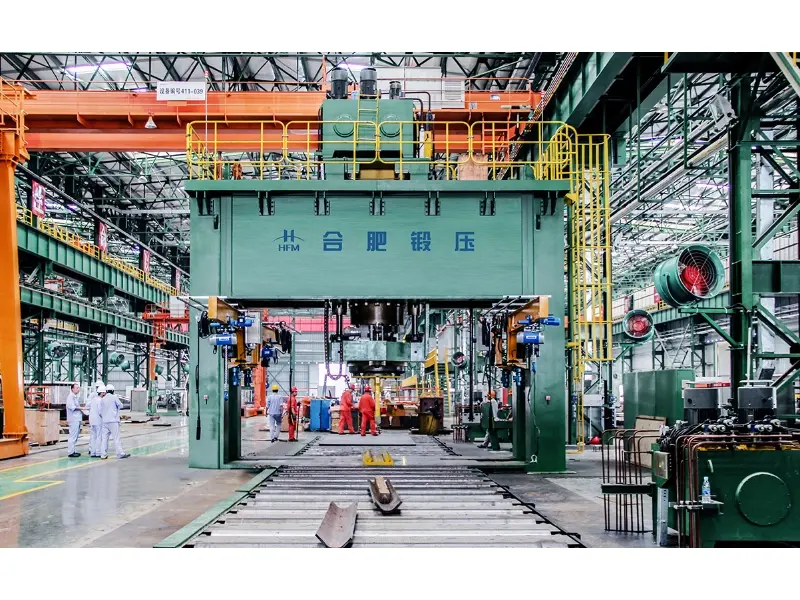

Precision hydraulic press for isothermal forging

Precision hydraulic press for isothermal forging

Application areas

Application areas