Brief description:

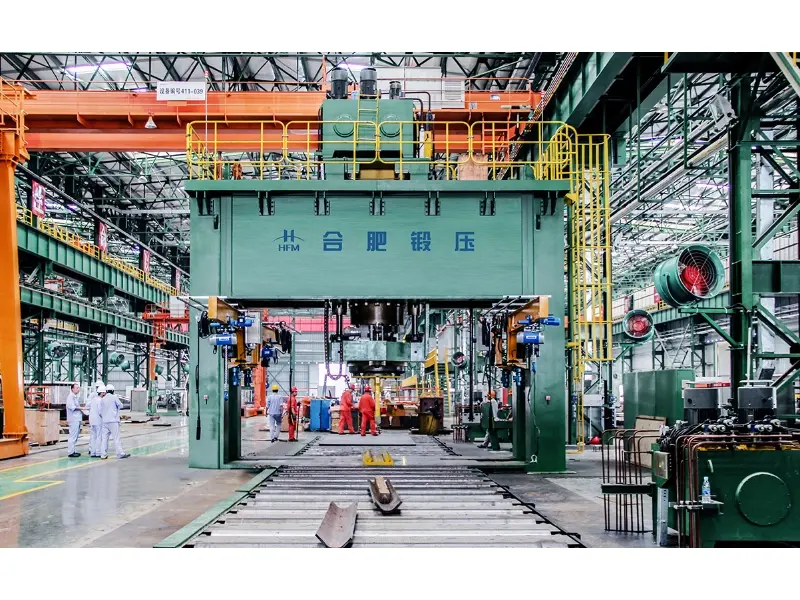

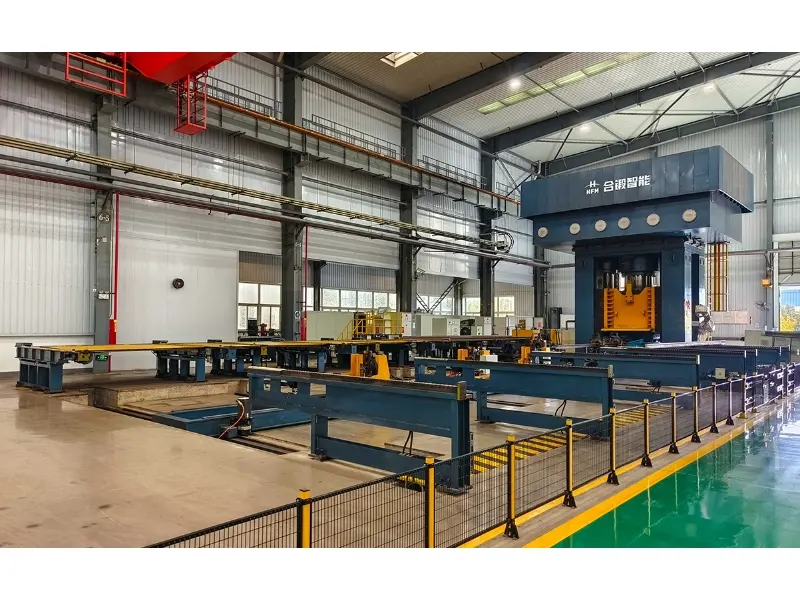

Hefei Metalforming Intelligent Manufacturing Co., Ltd. has been engaged in the forging field for many years, having developed a series of products including rapid forging, free forging, mold forging, isothermal forging, ring forging and so on, and accumulated rich experience and technology. We have been constantly improving the body structure of forging presses, control technology, automation level and productivity of the whole machine. The intelligent forging press production line developed by Hefei Metalforming Intelligent Manufacturing Co., Ltd. will essentially improve the conditions and environment of forging work. Through deep learning based on big data, it will greatly improve the technological level and quality of parts, and truly realize green, intelligent and informatized forging. At the same time, it is of strategic significance to enhancing the image, ability and industrial level of large-scale casting and forging industry and high-tech equipment manufacturing in our country.

Hefei Metalforming Intelligent Manufacturing Co., Ltd. has been engaged in the forging field for many years, having developed a series of products including rapid forging, free forging, mold forging, isothermal forging, ring forging and so on, and accumulated rich experience and technology. We have been constantly improving the body structure of forging presses, control technology, automation level and productivity of the whole machine. The intelligent forging press production line developed by Hefei Metalforming Intelligent Manufacturing Co., Ltd. will essentially improve the conditions and environment of forging work. Through deep learning based on big data, it will greatly improve the technological level and quality of parts, and truly realize green, intelligent and informatized forging. At the same time, it is of strategic significance to enhancing the image, ability and industrial level of large-scale casting and forging industry and high-tech equipment manufacturing in our country.

Keywords:

Production line of hydraulic presses for fast and free forging

Application areas

Application areas